Renexus has partnered with Urban Crop Solutions to provide turnkey solutions in the fast-emerging closed environment vertical farming industry. The solutions comprise using the best fully automated grow infrastructure using LED lighting that produces the healthiest and most cost efficient leafy greens whenever and wherever you want! With growth recipes for more than 200 crop varieties, we offer added value in the following industries: food production, food processing, R&D, retail, medicinal and industry (industrial crops). In the journey towards sustainability, clean energy is also part of the key solutions provided by Renexus Group. Our solutions help nations harness the power of renewable energy resources in the form of hydropower, biomass and solar. Renexus plays an instrumental role in conserving nature by reducing the use of natural gas & coal in electricity generation and utilize the resources to produce renewable energy to the country.

Proven indoor plant biology: your NET yield is the cornerstone of your protability. Proven factory engineering: 25+ Plant Factories and counting. End-to-End Solutions for your Return on Investment

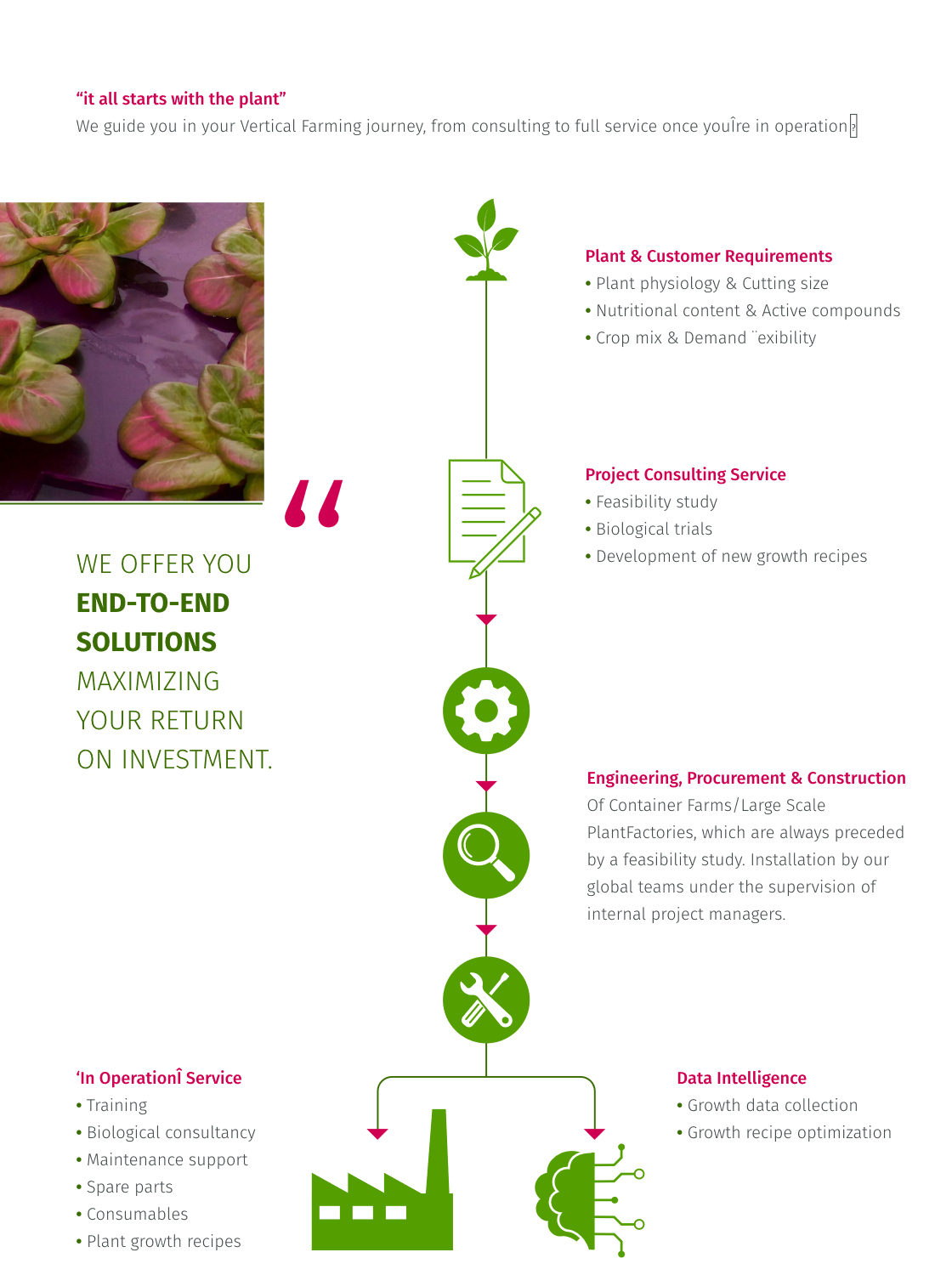

“Urban Crop Solutions” offers end-to-end solutions for Indoor Vertical Farming. It all starts with the crop: your crop and the needs of your market. Based on 5 years of research and real-life trials in our own research center, we help you select the right plant varieties with the right growth recipe for the requirements of your crop.

We design, manufacture, and install automated Plant Factories that can scale to the needs of your business. We help you in your journey to yield and support your first harvest. With us, you’ll be able to grow any crop under LED light anywhere on the planet, year-round

Grow where you sell. Save food miles and reduce food waste.

Crops are grown in an enclosed environment so there is no need for pesticides or herbicides.

Water transpired by the crops is captures and fed back to the crops.

Available year-round with consistent quality, independent of weather or climate change.

Grow crops in different climates, adapt your crop mix to your customer’s needs.

Consistent high quality, taste, freshness, nutritional value and active ingredients.

FOR YOUR SUCCESS (ROI), THERE ARE FOUR MAIN DRIVERS

Our factory engineers understand that it all starts with your customer’s crop specifications. Based on our Indoor Plant biology ‘Grow-How’, our team of experts has developed dedicated LED lighting, flexible fertigation, a dedicated climate system, and remote access control software.

HIGHEST NET YIELD

The output that goes to your customer

LOWEST INVESTMENT COST

per m2 or sq.ft of growing surface

LOWEST LABOR AND ELECTRICITY

per kg or lb of output

END-TO-END SUPPORT

We assist you in your Journey to Profit

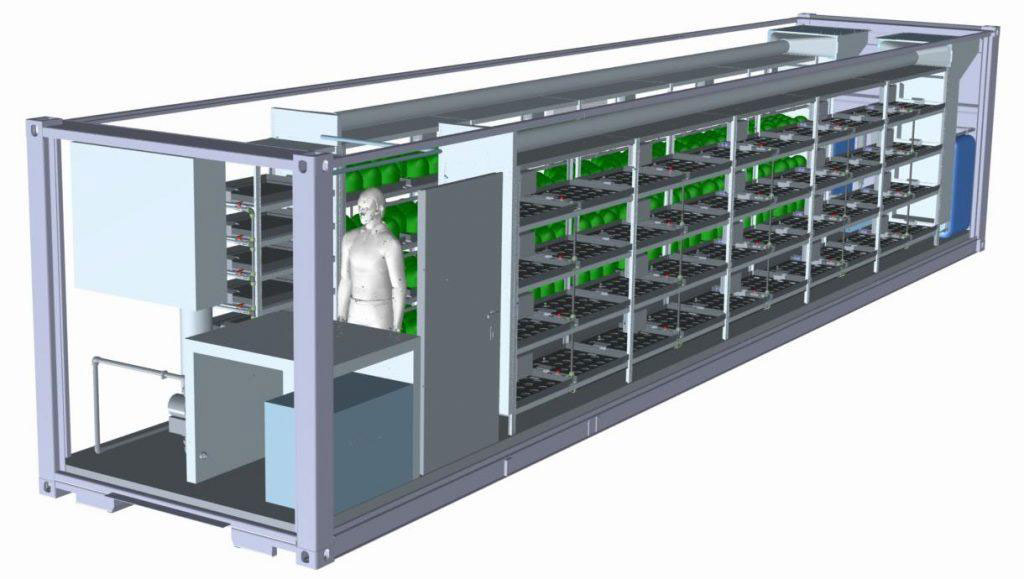

The FarmLAB is engineered based on the FarmFLEX, with upgrades for flexible LED lighting plans and extra software controls. All of this can be tailored to a specific crop and/or growth phase. Our customers have used the FarmLAB successfully for the research of wheat, banana plant propagation, flowers, hemp, and many others. The base price is 155.000 EUR for a 5-layer system or 3.690 EUR/harvest m² (343 EUR/sq. ft.)

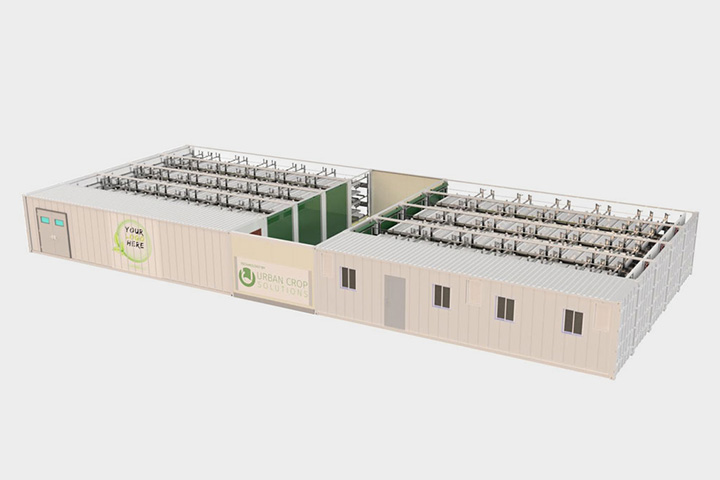

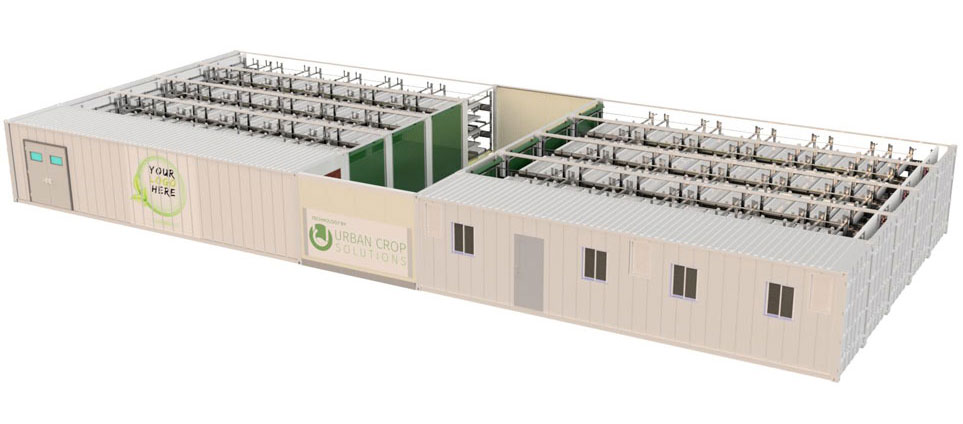

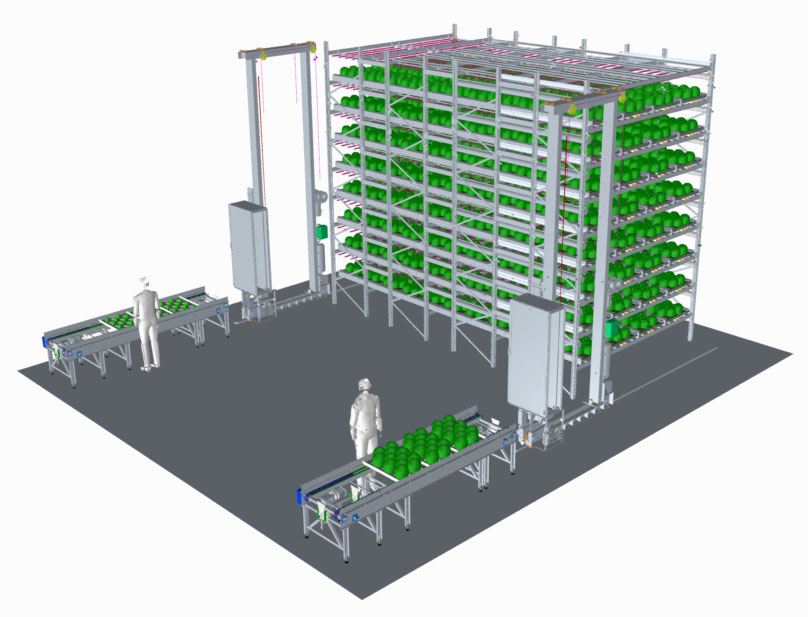

The ModuleX can be configured between 2 to 64 Grow Modules, so your PlantFactory is scalable with the growth of your business. One GrowModule features 86 m2 (926 sqft) of growing surface, yielding about 6.140 kg/year (13.530 lbs/year) of fresh vegetables. Each separate module allows for an independent climate and nutrient system, allowing your mix of crops to be adaptable to your customers’ needs.

The base price is an industry-low CAPEX of 1.950 EUR/m2 per growing surface (approx. 181 EUR/sq.ft). The labour costs are reduced by the automated crop-to-person ‘BenchCarousel’. This is the most efficient solution to maximize your return on investment.

A PlantFactory is custom engineered and constructed within an existing or new stand-alone building. A fully automated solution, with a growing surface larger than 5000 m2 (53.800 sq.ft). Economies of scale allow for extensive automation and labor cost savings in crop handling and processing. Suitable for production of leafy greens, herbs, microgreens, and medicinal plants. Base price starts at 2.750 EUR/harvest m2 (255 EUR/sq. ft). This can increase depending on the level of automation required for handling and crop processing after harvest.

We offer you research and “Grow-How” in our 10 controlled environment growth chambers, 1 FarmPro and 1 ModuleX for crop cultivar screening, nutrient formulations, plant cultivation techniques, LED light spectrum research, hydroponic irrigation and substrate development. The ‘Grow-How’ of our scientists with 30+ years of experience, enables us to serve customers with the support of 200+ recipes.

Start up small. Minimize your initial CAPEX, and build your showcase farm with a ModuleX-2.

As you develop new routes to the market around you, when you attract more customers, then scale-up in a smart way.

Add Grow Modules as you need, with a fast 12-week lead time. And grow your business to a ModuleX-64 and beyond

Each Grow Module has an independent ClimateZone and Nutrient system.

Grow Genovese Basil in the ‘Italian’ ClimateZone, and grow microgreens the Grow Module right next to it, in a ‘Belgian’ Climate with a separate optimized nutrient mix. Adapt your mix of crops to the needs of your customers.

Reduce your labor cost while each growing bench comes to you within 90 seconds with the push of a button; made possible by the BenchCarousel.

Reduce your CAPEX to 1800 EUR/m2 (167 EUR/sq.ft), because 1 Grow Module contains an industry-best 86m2 (926 sq.ft) growing surface. Achieve your maximum yield when your crops receive 100% of the light, (almost) 100% of the time.

We can mimic any climate on earth within our labs. To validate yields and improve plant growth recipes in our factories, we also operate a full-scale FarmPro container farm, and a ModuleX Grow Module.

Our main activities are crop variety screening, enhancing nutrient formulations and perfecting plant cultivation techniques. We have developed our own LED light technology, and continue our experiments to enhance plant response to LED light spectrum and intensity.

We carefully select the components you need to achieve the most effective configuration for your situation. We have the highest precision when it comes to controlling all environmental variables : temperature, humidity, airflow, LED light, air flow, irrigation and nutrient formulation.

For a client active in the green roof industry, our Indoor Plant Biologists have increased the growth speed of succulents by factor 3 compared to open field production.

Plant based medicine is an important trend. We’ve researched the promotion of active compounds in plants such as: Valerian, Artemesia, Lemon balm, St John’s-wort and Coneflower.

Active compound optimisation and yield increase for Stevia has been investigated. Our team also conducted environmental research for high-quality Saffron.

Multiple crops varieties have been trialed for yield analysis: Marigold, Nasturtium, Borage, Violet, Viola, Zucchini flower, Dandelion.

For a corporate research department, we’ve conducted plant growth recipe development for high-speed growth for dwarf wheat varieties.

Various fruiting crops such as mini-tomato, strawberries, mini-zucchini, peppers and eggplant have been assessed for their application in indoor farming.